Cov Kab Ntau Lawm PVC Uas Muaj Peev Xwm Ntau

Cov Ntawv Thov Khoom

Tam sim no, peb cov kab tsim cov yeeb nkab PVC siv tau los tsim cov yeeb nkab PVC-U, cov yeeb nkab dej PVC-U, cov yeeb nkab PVC-U radially reinforced, cov yeeb nkab PVC-U ob phab ntsa corrugated, thiab cov yeeb nkab PVC-U kauv muffler, thiab lwm yam.

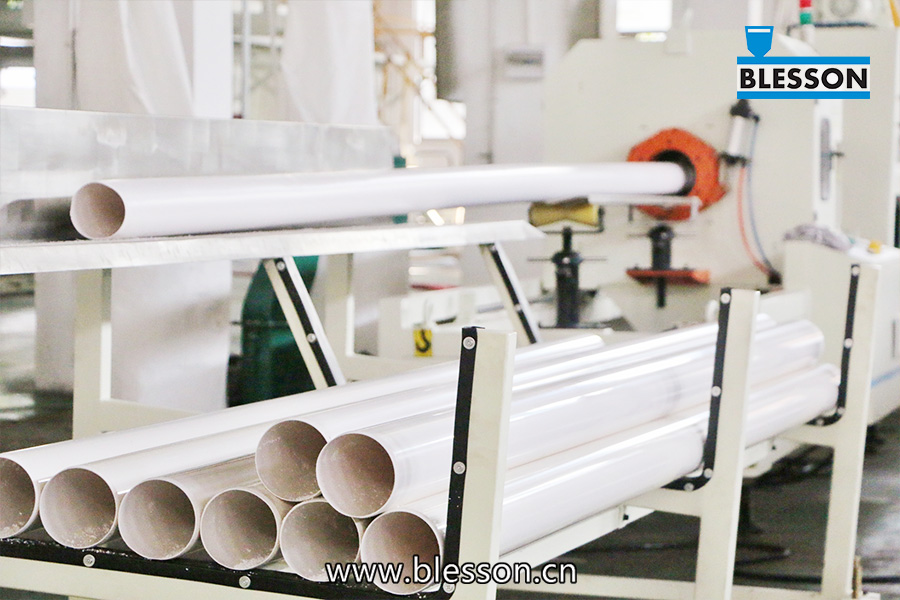

(1) Cov kav dej PVC-U

Cov kav dej PVC-U siv tau rau hauv kev tsim cov kav dej hauv tsev, cov kav dej hauv nroog, cov kav dej hauv vaj thiab cov kav dej phwj, thiab lwm yam. Nws muaj ntau yam zoo, xws li tiv taus tshuaj lom neeg, tiv taus kua qaub thiab alkali, tiv taus siab, tsis muaj kuab paug, phab ntsa sab hauv du, thiab tsis cuam tshuam rau qhov zoo ntawm dej, thiab lwm yam zoo.

(2) Cov kav dej ntws PVC-U

Ua ib lub yeeb nkab yas siv ntau tshaj plaws hauv kev tsim dej ntws, cov yeeb nkab PVC-U muaj qhov zoo ntawm kev tsim kho yooj yim, kev siv yooj yim, kev tiv thaiv corrosion zoo, lub neej ntev thiab kev nyab xeeb ntawm cov yeeb nkab. Nws tau siv dav hauv ntau yam lag luam, suav nrog kev tsim kho dej ntws, kev lim dej phwj tuaj, kev ntws dej hauv nroog thiab kev ntws tshuaj lom neeg, thiab lwm yam.

(3) PVC fais fab cable duct

Cov kav hlau fais fab PVC feem ntau yog siv rau hauv kev sib txuas lus, kev tiv thaiv cable thiab cov kav dej sib txuas lus ntawm txoj kev loj, thiab lwm yam. Nws muaj qhov zoo ntawm kev tiv thaiv corrosion muaj zog, tiv thaiv kub zoo, lub teeb yuag, tiv thaiv kev laus thiab kev teeb tsa yooj yim.

(4) PVC-U radially reinforced yeeb nkab

Ua ib hom yeeb nkab PVC-U tshiab, cov yeeb nkab PVC-U radially reinforced yog tus cwj pwm los ntawm kev txo cov phab ntsa tuab thiab txhim kho qhov kev tiv thaiv siab. Phab ntsa sab nraud ntawm cov yeeb nkab muaj cov kab radial reinforcing ribs los txhim kho qhov nruj thiab lub zog compressive ntawm cov yeeb nkab, thiab yog tsim rau cov dej ntws thiab cov dej phwj hauv kev tsim kho hauv nroog. Cov yeeb nkab PVC-U radially reinforced muaj qhov zoo ntawm qhov hnyav sib dua, kev thauj mus los yooj yim, kev tiv thaiv corrosion, kev ua tau zoo tiv thaiv kev xau, phab ntsa sab hauv du thiab lub neej ua haujlwm ntev.

(5) PVC-U kauv muffler yeeb nkab

Cov yeeb nkab PVC-U kauv muffler siv cov qauv kauv tshwj xeeb, uas txo qhov cuam tshuam rau phab ntsa sab hauv ntawm cov yeeb nkab thaum lub sijhawm ntws dej thiab txo cov suab nrov. Nws tuaj yeem siv rau cov dej ntws ntawm cov haujlwm tsim kho thiab cov dej ntws hauv nroog. Nws muaj peev xwm ntws dej loj, lub zog yeeb nkab siab, thiab kev teeb tsa yooj yim.

(6) Cov yeeb nkab PVC-C

Cov kav dej PVC-C siv dav hauv cov kav dej txias thiab dej kub rau pej xeem thiab cov lag luam thiab cov kav dej haus ncaj qha. Lawv tuaj yeem siv rau kev thauj mus los ntawm dej kub, cov kua thiab cov pa roj uas tiv taus xeb. Lawv tuaj yeem muab faib ua cov kav dej tua hluav taws PVC-C thiab cov kav dej txias thiab dej kub PVC-C. Cov kav dej tua hluav taws PVC-C muaj qhov zoo ntawm kev tiv taus cua sov, kev tiv taus hluav taws thiab kev txuag hluav taws xob. Cov kav dej kub thiab dej txias PVC-C muaj qhov zoo ntawm kev tiv taus xeb, kev tiv taus sulfuric acid muaj zog, kev tiv taus alkali muaj zog, cov kab mob tsis yooj yim loj hlob, kev teeb tsa sai, thiab kev tiv thaiv ib puag ncig.

Cov Ntsiab Lus Tseem Ceeb

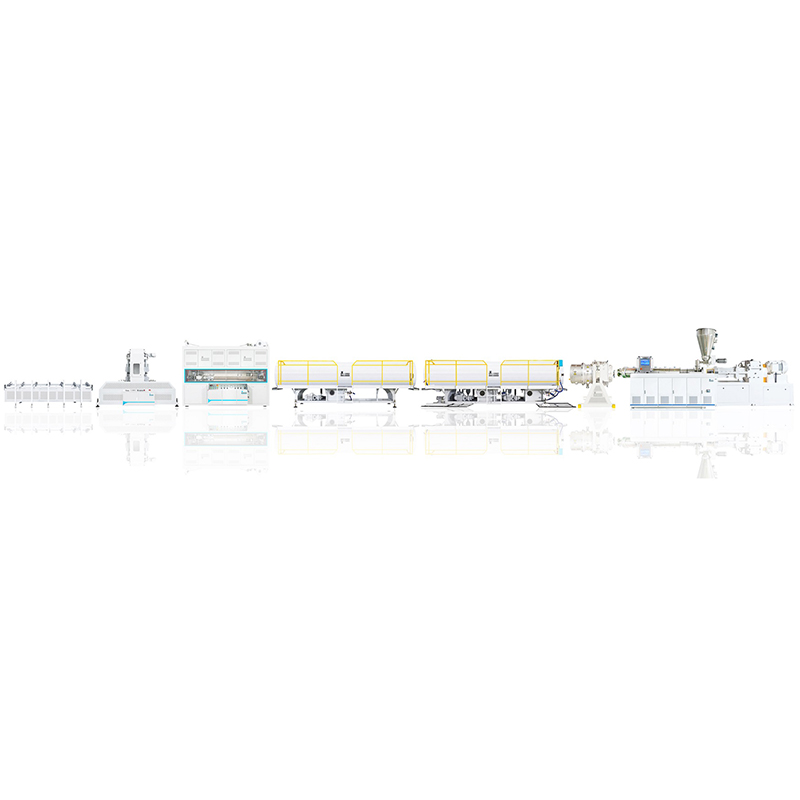

● Cov kab tsim cov yeeb nkab PVC uas tsim los ntawm Guangdong Blesson Precision Machinery Co., Ltd. muaj kev teeb tsa tsim nyog, thev naus laus zis laus thiab kev tsim qauv raws li tib neeg. Kev lag luam thiab kev siv tau ntawm peb cov kab tsim cov yeeb nkab tau lees paub los ntawm peb cov neeg siv khoom, thiab kev ua tau zoo ntawm tus nqi siab dua li qib nruab nrab hauv kev lag luam.

● Kev tsim qauv siab ntawm kev siv tshuab tuaj yeem txuag tau tus nqi ntawm cov peev txheej tib neeg, xyuas kom meej tias cov kab tsim yeeb nkab ua haujlwm tau yooj yim, thiab muaj kev tswj hwm siab thiab kev sib dhos zoo heev.

Tshuab Extruder

● Raws li cov neeg siv khoom nyiam, peb cov kab tsim cov yeeb nkab PVC tuaj yeem nruab nrog conical twin-screw extruder lossis parallel twin-screw extruder. Lub extruder muaj lub kaw lus pub mov ntau, uas tuaj yeem tswj tau los ntawm kev hloov pauv zaus thiab kev tswj ceev, thiab muaj lub tswb ceeb toom txhaum thiab kev tiv thaiv kev thauj khoom ntau dhau. Nws muaj qhov zoo ntawm qhov ntim extrusion loj, qhov nrawm shear me me thiab nyuaj rau decomposition ntawm cov khoom.

● Tus qauv ntsia hlau ntawm lub tshuab extruder twin-screw yog scientific thiab tsim nyog. Lub ntsia hlau tau dhau los ua kev kho mob zoo xws li nitriding thiab high-frequency quenching kom ntseeg tau tias muaj kev sib xyaw zoo thiab cov nyhuv plasticizing, thiab tag nrho cov pa tawm. Lub cuab yeej tswj qhov kub thiab txias uas muaj lub ntsia hlau tuaj yeem tswj tau qhov kub thiab txias ntawm cov khoom siv zoo dua.

Pwm

● Blesson PVC yeeb nkab pwm tuaj yeem tsim cov yeeb nkab PVC nrog ntau yam diameters los ntawm 16mm mus rau 1000mm.

● Cov pwm yeeb nkab PVC uas Blesson tsim los siv lub pwm shunt shuttle bracket hom, nrog rau kev tsim qauv khiav zoo tshaj plaws, thiab cov qauv pwm yooj yim-rau-rhuav tshem kom ntseeg tau tias cov nyhuv plasticization ntawm PVC, txhim kho kev ua haujlwm ntawm cov khoom siv, thiab tus neeg siv tuaj yeem hloov pwm thiab kho qhov siab nruab nrab thiab lub kaum sab xis ntawm pwm raws li qhov xav tau tiag tiag.

● Hais txog cov txheej txheem tsim pwm, peb cov pwm yog ua los ntawm cov hlau pwm zoo, uas yog tsim los ntawm kev forging, machining rough, quenching thiab tempering, khiav nto rough polishing thiab fine polishing, mechanical finishing thiab hardening thiab anti-corrosion kho. Cov txheej txheem tsim khoom txheem ua kom ntseeg tau tias cov pwm muaj cov khoom ruaj khov zoo thiab hnav tsis kam thiab corrosion tsis kam. Cov yas kuj muaj cov kua dej zoo hauv pwm.

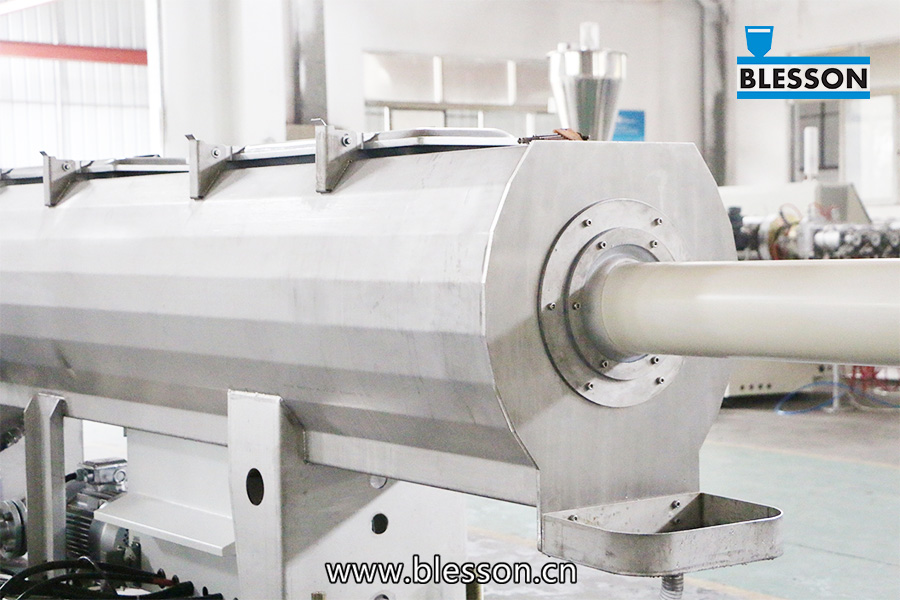

Lub tshuab nqus tsev

● Lub thawv nqus tsev siv cov qauv dej thiab dej ntws zoo tshaj plaws los xyuas kom meej tias cov kav dej huv, uas txo qhov nyuaj thiab lub sijhawm ntawm kev teeb tsa thiab kev saib xyuas. Lub cev lub thawv nqus tsev, cov kav dej, cov khoom siv kav dej, thiab lwm yam yog ua los ntawm cov hlau tsis xeb SUS304 zoo, uas ua rau lub zog tiv thaiv xeb zoo dua. Lub hau txhuas hnyav thiab lub nplhaib roj hmab peb txheej ntawm lub thawv nqus tsev ua kom muaj kev sib khi zoo dua. Lub twj tso kua mis nqus tsev ua kom cov khoom ruaj khov thiab zoo. Cov dej txau uas teeb tsa zoo thiab lub zog dej ruaj khov ua rau cov kav dej txias sai thiab sib npaug. Kev tswj qib dej thiab kev tswj kub dej kom raug ua rau cov kav dej PVC txias thiab ua kom zoo dua. Lub lim dej loj thiab txoj kev hla mus tom ntej tuaj yeem ntxuav cov khoom tsis huv hauv cov dej txias, thiab tuaj yeem ntxuav lub lim dej sai yam tsis tas nres lub tshuab.

Chav thauj khoom

● Raws li qhov yuav tsum tau ua ntawm ntau qhov loj ntawm cov yeeb nkab sib txawv, peb lub tuam txhab tau tsim ntau yam kev thauj khoom kom haum rau cov kab ntau lawm. Txij li kev siv txoj siv rau cov yeeb nkab me me, kev thauj ob lub kab ntsig, kev thauj peb lub kab ntsig, kev thauj plaub lub kab ntsig hla, thiab lwm yam, mus rau kev thauj kaum ob lub kab ntsig, txhua hom muaj.

● Txhua lub caterpillar muaj lub servo motor drive uas ywj pheej, thiab qhov ceev ntawm txhua lub caterpillar yog ua kom ntseeg tau los ntawm lub digital controller. Cov roj hmab caterpillar uas tsim tshwj xeeb ua rau kev sib txhuam hauv cov txheej txheem thauj khoom zoo dua, txo cov teeb meem slipping, thiab yooj yim rau kev teeb tsa thiab hloov.

Chav txiav

● Rau cov kav dej PVC uas muaj qhov me me thiab nruab nrab, peb lub tuam txhab tau tsim lub tshuab txiav tsis muaj chip; qhov kev tsim clamping ntau lub ntsiab lus rau cov kav dej me me thiab nruab nrab tuaj yeem hloov kho tau yam tsis tas hloov lub cuab yeej, txo lub sijhawm hloov qhov loj ntawm cov kav dej thaum lub sijhawm tsim khoom. Rau cov kav dej uas muaj qhov nruab nrab thiab loj, peb lub tuam txhab siv cov chaw txiav planetary nrog ntau qhov txiav sib txawv kom tau raws li qhov xav tau ntawm kev tsim khoom. Peb lub tshuab txiav siv lub tshuab hydraulic zoo kom ntseeg tau tias muaj zog tsav tsheb ruaj khov. Kev ruaj khov ntawm clamping, kev tig raug thiab kev sib dhos ntawm lub tshuab txiav mus tom ntej thiab rov qab ua kom ntseeg tau tias kev txiav du thiab sib npaug ntawm cov kav dej PVC.

Tshuab ntsaws qhov (socketing machine)

● Raws li kev siv cov yeeb nkab PVC sib txawv, lub tshuab socketing uas peb lub tuam txhab tsim tawm tuaj yeem ua U-puab socketing, ncaj socketing thiab rectangular socketing. Lub tshuab socketing tuaj yeem ua kom sov ob txheej sab hauv thiab sab nraud ntawm cov yeeb nkab PVC kom ntseeg tau tias qhov loj ntawm socketing raug. Lub tshuab socketing siv txoj kev tsim hydraulic sab nraud kom ntseeg tau tias cov duab ntawm cov yeeb nkab PVC tom qab socketing yog sib xws nrog cov duab ntawm cov pwm socketing, thiab qhov zoo ntawm cov yeeb nkab PVC tau zoo dua.

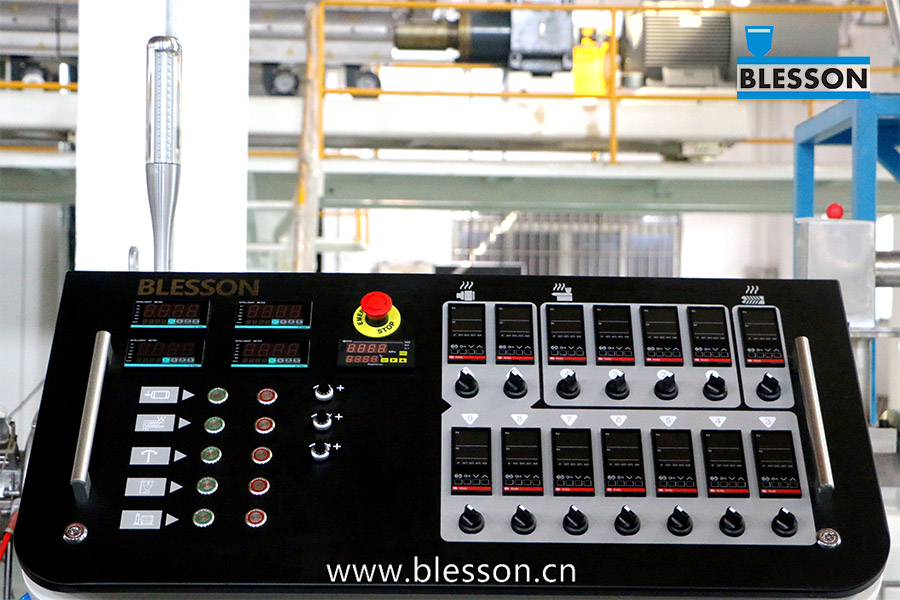

Kev tswj hwm

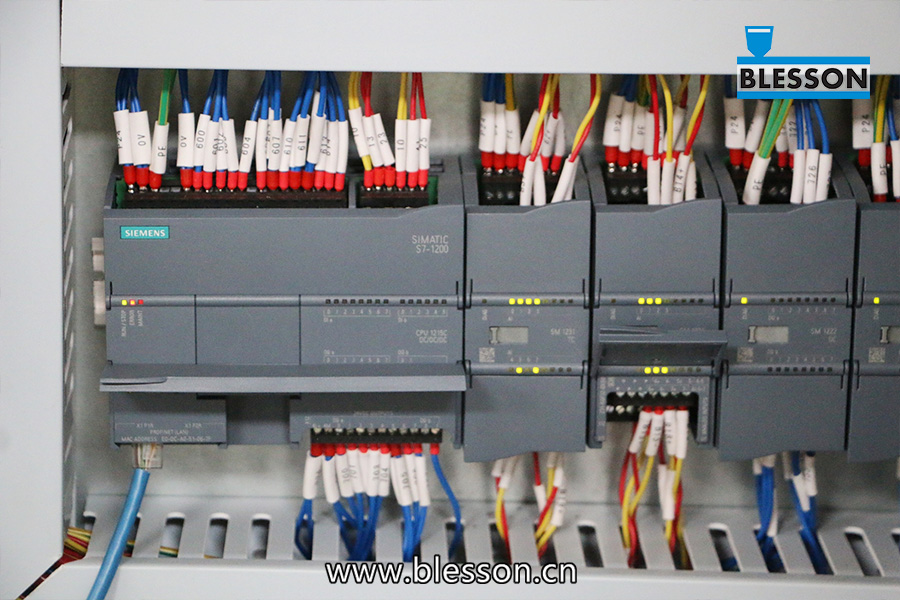

● Kev tsim qauv ntawm ntau txoj kev tiv thaiv ua kom cov khoom siv tsis puas tsuaj rau hauv cov xwm txheej tsis zoo. Peb lub tuam txhab siv cov khoom siv hluav taws xob zoo, xws li Siemens, ABB thiab Schneider, thiab lwm yam, los xyuas kom meej tias cov kab ntau lawm ruaj khov thiab muaj kev nyab xeeb, thiab txhim kho qhov yooj yim ntawm kev hloov cov khoom siv hluav taws xob tom qab muag.

● Peb cov kab tsim cov yeeb nkab PVC tuaj yeem xaiv hom kev tswj tes lossis hom kev tswj PLC.

● Txoj kev tswj tes yog tswj los ntawm OMRON lossis TOKY qhov kub thiab txias, uas yooj yim rau kev saib xyuas tom qab muag.

● Hom kev tswj PLC siv cov thev naus laus zis sib xyaw ua ke ntawm Siemens S7-1200 series PLC los ua kev xam, ntsuas, tswj kub thiab tswj kev txav mus los ntawm lub kaw lus extrusion, paub txog cov haujlwm automation ntawm cov kab tsim khoom PVC yeeb nkab, txhim kho qib automation ntawm cov kab tsim khoom, thiab txo tus nqi ntawm cov peev txheej tib neeg.

● Lub vijtsam kov Siemens tus txiv neej-tshuab interface tuaj yeem sau cov ntaub ntawv mis thiab cov ntaub ntawv tsim khoom, uas yooj yim rau cov neeg siv los tswj kev ua haujlwm ntawm cov kab ntau lawm. Tib lub sijhawm, tus neeg siv tuaj yeem txiav txim siab sai sai qhov ua rau muaj qhov txhaum thiab tshem tawm qhov txhaum los ntawm kev ua haujlwm ceeb toom.

● Cov nyees khawm tes tau teeb tsa hauv qab PLC tswj vaj huam sib luag, uas tuaj yeem hloov kho cov haujlwm ib txwm muaj xws li qhov ceev ntawm extruder, kev thauj khoom ceev thiab kev sib dhos yam tsis tas yuav tshem cov hnab looj tes tiv taus cua sov.

● Los ntawm PROFIBUS module ntawm Siemens PLC, cov ntaub ntawv ntawm txhua yam khoom siv tuaj yeem sib xyaw ua ke, thiab cov khoom siv tuaj yeem saib xyuas thiab tswj tau yooj yim dua los ntawm kev tswj hwm fieldbus, thiab kev ua haujlwm ntawm cov kab ntau lawm ruaj khov dua.

Daim Ntawv Teev Qauv

| PVC Yeeb Nkab Tsim Kab | |||||

| Qauv Kab | Txoj kab uas hla (hli) | Qauv Extruder | Qhov Tso Tawm Siab Tshaj (kg/h) | Qhov Ntev ntawm Kab (m) | Tag Nrho Lub Hwj Chim Teeb Tsa (kW) |

| BLS-63 PVC | 16-63 | BLE55-120 | 200 | 20 | 95 |

| BLS-63CPVC | 16-63 | BLE65-132 | 180 | 28 | 105 |

| BLS-110 PVC (Kuv) | 63-110 | BLE80-156 | 450 | 27 | 180 |

| BLS-110 PVC (II) | 20-110 | BLE65-132 | 280 | 27 | 110 |

| BLS-110 PVC(III) | 63-110 | BLE65-132G | 450 | 28 | 100 |

| BLS-160 PVC (Kuv) | 63-160 | BLE80-156 | 450 | 30 | 175 |

| BLS-160 PVC (II) | 40-160 | BLE65-132 | 280 | 27 | 125 |

| BLS-160 PVC(III) | 110-160 | BLE92-188 | 850 | 40 | 245 |

| BLS-160 PVC (III) | 75-160 | BLE65-132 | 280 | 27 | 125 |

| BLS-160 PVC (III) | 40-160 | BLP75-28 | 350 | 27 | 95 |

| BLS- 250 PVC (I) | 63-250 | BLE80-156 | 450 | 34 | 195 |

| BLS- 250 PVC (II) | 63-250 | BLE65-132 | 280 | 34 | 145 |

| BLS-250 PVC (III) | 110-250 | BLE-92-188 | 850 | 45 | 265 |

| BLS-250 PVC (III) | 50-250 | BLE65-132 | 280 | 29 | 210 |

| BLS-315(Kuv) | 63-315 | BLE80-156 | 450 | 34 | 230 |

| BLS-250 PVC (III) | 110-250 | BLP90-28 | 600 | 44 | 160 |

| BLS-250 PVC (IIIIII) | 63-250 | BLE65-132G | 450 | 35 | 100 |

| BLS-315 PVC (II) | 63-315 | BLE65-132G | 450 | 35 | 120 |

| BLS-400 PVC (Kuv) | 110-400 | BLE92-188 | 850 | 45 | 290 |

| BLS-400 PVC (II) | 180-400 | BLE95-191 | 1050 | 45 | 315 |

| BLS-400 PVC (III) | 180-400 | BLP114-26 | 800 | 50 | 250 |

| BLS-630 PVC (Kuv) | 160-630 | BLE92-188 | 850 | 45 | 330 |

| BLS-630 PVC (II) | 160-630 | BLP114-26 | 900 | 48 | 510 |

| BLS-800 PVC (Kuv) | 280-800 | BLE95-191 | 1050 | 46 | 380 |

| BLS-800 PVC (II) | 280-800 | BLP130-26 | 1100 | 42 | 280 |

| BLS-1000 PVC | 630-1000 | BLE95-191 | 1050 | 52 | 540 |

Kev Pov Thawj, Daim Ntawv Pov Thawj Ua Raws Cai

Guangdong Blesson Precision Machinery Co., Ltd. muab kev pabcuam lav ib xyoos. Thaum lub sijhawm siv cov khoom, yog tias koj muaj lus nug txog cov khoom, koj tuaj yeem tiv tauj peb ncaj qha rau kev pabcuam tom qab muag.

Guangdong Blesson Precision Machinery Co., Ltd. muab daim ntawv pov thawj tsim nyog rau txhua yam khoom muag, kom ntseeg tau tias txhua yam khoom tau raug tshuaj xyuas los ntawm cov kws tshaj lij thiab cov neeg kho qhov yuam kev.

Cov Ntaub Ntawv Txog Lub Tuam Txhab