Cov Kab Ntau Lawm PVC Twin Pipe Production Line 2-strand Pipe Extrusion Tshuab

Cov Ntawv Thov Khoom

Cov kab ntau lawm PVC twin-pipe los ntawm Guangdong Blesson Precision Machinery Co., Ltd. tuaj yeem tsim cov kav dej PVC, cov kav dej ntws PVC, cov kav dej kub CPVC, cov kav dej siab PVC, thiab lwm yam.

PVC conduit muaj cov yam ntxwv ntawm kev ua haujlwm hluav taws kub siab nrog lub zog tensile thiab cuam tshuam zoo heev, uas yog qhov tsim nyog rau kev sib txuas lus, kev thauj mus los, kev tsim kho hauv nroog thiab lwm yam teb.

Cov kav dej PVC siv dav hauv cov haujlwm kav dej sab hauv tsev thiab sab nraum zoov hauv cov tsev. Tsis yog tsuas yog qhov piv ntawm kev nthuav dav ntawm cov kav dej tsawg xwb, tab sis qhov kev hloov pauv uas cuam tshuam los ntawm qhov kub thiab txias kuj txwv.

Cov kav dej kub thiab txias CPVC ib puag ncig muaj kev ua tau zoo heev ntawm lub zog siab, tiv taus kub zoo. Qhov kub ua haujlwm siab tshaj plaws tuaj yeem ncav cuag 95 °.

Cov Ntsiab Lus Tseem Ceeb

Blesson PVC twin yeeb nkab ntau lawm kab

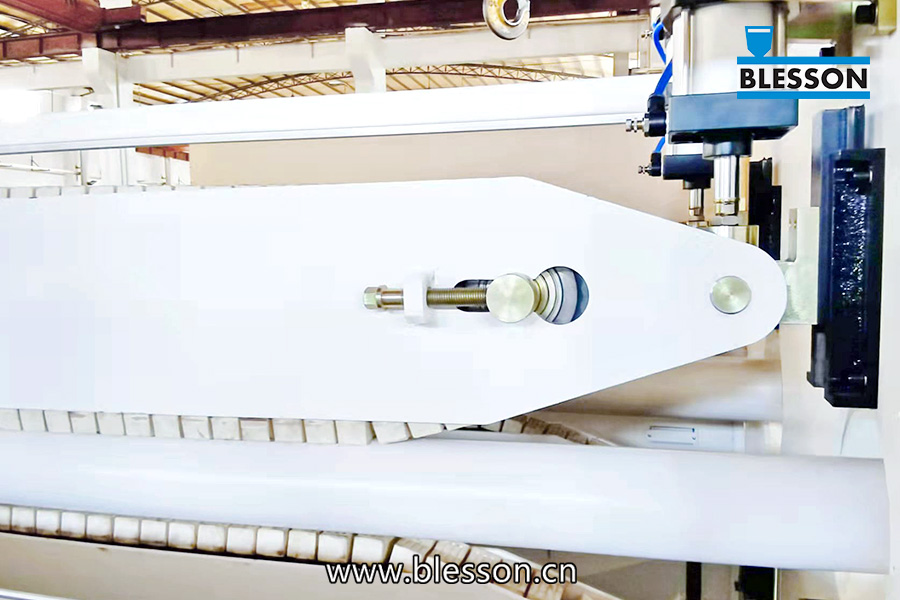

● Lub Tshuab Extruder Conical Twin-Screw/Parallel Twin-Screw uas ua haujlwm tau zoo heev:

Cov kab ntau lawm PVC twin-pipe uas tsim los ntawm Guangdong Blesson Precision Machinery Co., Ltd. muaj cov khoom siv txuag hluav taws xob.conical twin ntsia hlau extruder or parallel twin ntsia hlau extruderYuav kom lav qhov kev sib xyaw ua ke thiab cov yas zoo, peb lub tshuab extruder ntxaib siv cov qauv tsim ntsia hlau tsim nyog nrog qhov nrawm qis kom tsis txhob muaj cov khoom siv PVC rhiab heev uas yooj yim puas tsuaj.

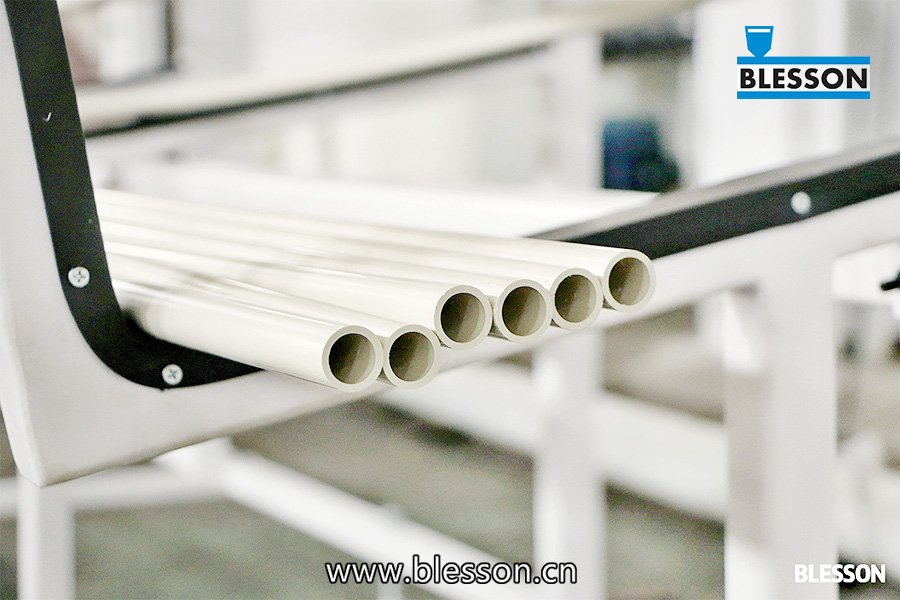

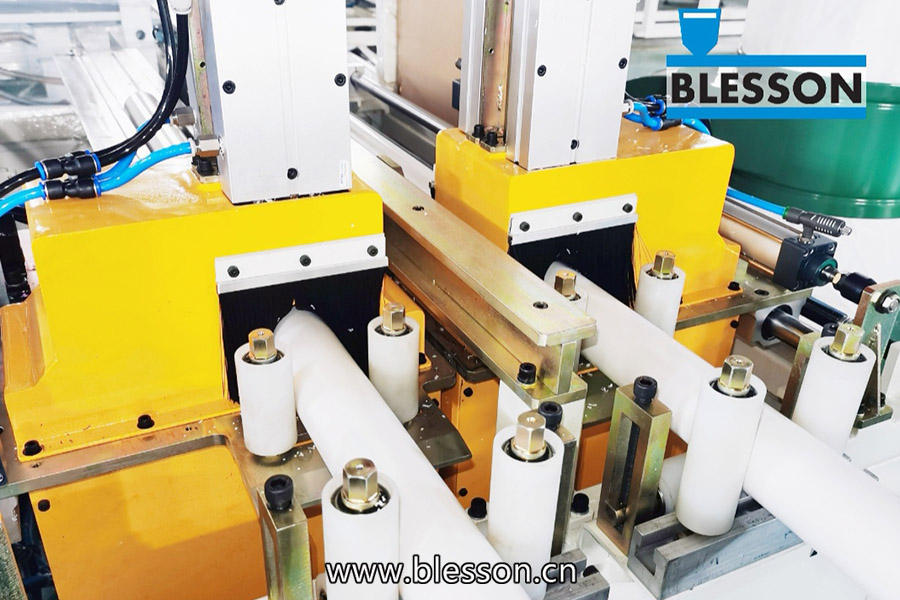

● Kab Ntau Lawm PVC Twin Pipe 2-strand PVC Pipe Extrusion Die:

1. Lub taub hau tuag ntawm PVC twin-pipe ntau lawm kab ntawm Guangdong Blesson Precision Machinery Co., Ltd. siv cov qauv tsim kho siab heev.

2. Tus qauv tsim ntawm cov dej ntws ua kom ntseeg tau tias cov khoom siv tuaj yeem sau cov dej ntws tag nrho thiab tuaj yeem sib npaug extruded, tib lub sijhawm tiv thaiv kev lwj ntawm cov khoom siv PVC los ntawm overheating.

3. Los ntawm kev hloov lub bush, pin thiab calibrator sleeve ntawm PVC twin-pipe extrusion die, cov neeg siv khoom tuaj yeem hloov pauv cov khoom mus rau ntau qhov ntau thiab tsawg ntawm cov yeeb nkab.

4. Lub pwm extrusion twin-pipe ntawm Blesson PVC twin-pipe ntau lawm kab siv cov hlau zoo tshwj xeeb tshaj yog rau pwm. Tom qab polishing, hardening, thiab nitriding kho, peb lub pwm extrusion twin-pipe ruaj khov dua.

5. Cov kab tsim khoom ob txoj hlua PVC ntxaib muaj txiaj ntsig zoo dua li cov kab tsim khoom ib txoj hlua, uas tuaj yeem txuag tau kev siv hluav taws xob ntau lawm, txo cov nqi av, thiab kov yeej qhov nyuaj ntawm cov txiaj ntsig qis rau cov kav dej me.

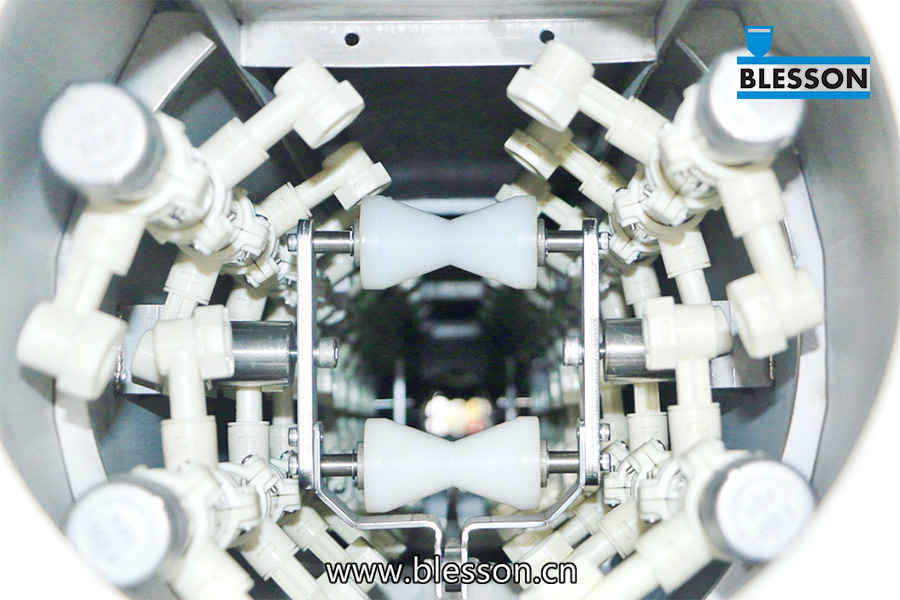

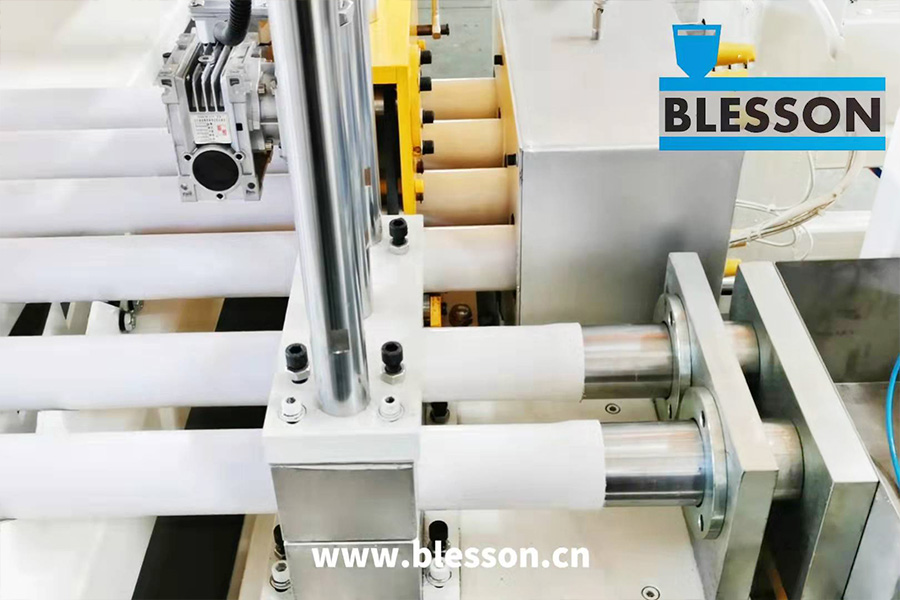

● Chav Ua Haujlwm Ob Chav Haul Off ntawm PVC Twin-Pipe Production Line:

1. Raws li lub raj xa dej ntawm cov kav dej PVC, cov neeg siv khoom tuaj yeem xaiv ob txoj siv thauj khoom lossis ob txoj kab uas hla kab ntsig.

2. Peb lub tshuab thauj khoom siv ob txoj siv yog tswj los ntawm lub cev muaj zog sib nqus tas mus li nrog kev ceev ceev thiab suab nrov qis.

3. Lub caterpillar sab saud ntawm peb lub raj xa dej ob chav chaw nres tsheb siv txoj kev clamping pneumatic, thaum lub qis dua siv txoj kev nqa hluav taws xob synchronous. Qhov kev tsim no ua kom lub caterpillar thiab cov yeeb nkab tswj tau qhov siab sib cuag kom zoo, thiab txhim kho kev sib dhos thiab kev ruaj khov ntawm lub tshuab thauj khoom.

4. Lub encoder siab-precision tuaj yeem ntsuas qhov ntev ntawm cov yeeb nkab hauv lub sijhawm tiag tiag.

5. Cov roj hmab thaiv ntawm lub caterpillar haul-off unit kho los ntawm kev ntsia hlau installation yog khov kho thiab txhim khu kev qha thiab yooj yim rau disassemble rau kev hloov.

● Chav Txiav Ob Chav Ua Haujlwm ntawm Blesson PVC twin yeeb nkab ntau lawm kab:

1. Raws li cov yeeb nkab sib txawv, peb lub tuam txhab tuaj yeem muab cov yeeb nkab ob chav chaw nres tsheb lossis ob chav chaw nres tsheb pom txiav chav tsev.

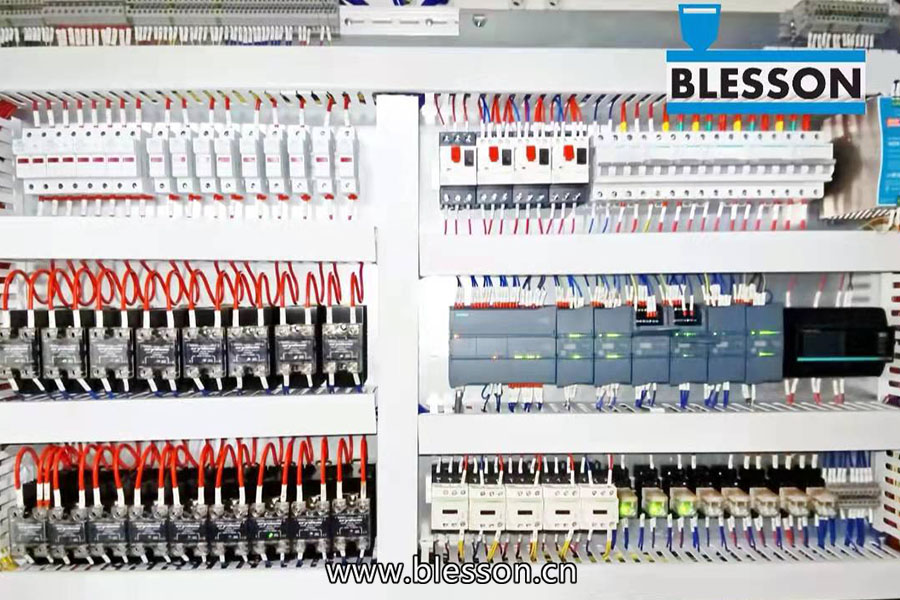

2. Peb lub tshuab txiav planetary thiab ob chav kaw hniav txiav yog tswj los ntawm Siemens PLC kov lub vijtsam, uas yooj yim rau teeb tsa hom txiav. Cov chav txiav tau nruab nrog lub tsev tiv thaiv hlau kom ntseeg tau tias tus neeg teb xov tooj muaj kev nyab xeeb. Nrog lub cuab yeej nqus plua plav muaj zog, peb lub tshuab txiav tuaj yeem txo cov plua plav uas tau sau thaum txiav cov yeeb nkab.

● Lub tshuab ntsaws qhov (socketing machine) uas muaj plaub lub qhov cub cua sov thiab ob lub qhov cub ntsaws qhov rau cov kab tsim khoom PVC ob lub yeeb nkab:

1. Peb lub tuam txhab tuaj yeem hloov kho qhov socketing tsis siv neeg tag nrhotshuab raws li qhov xav tau tiag tiag ntawm ntau tus neeg siv khoom thoob plaws ntiaj teb. Blesson tag nrho tsis siv neegkev txuas qhov (socketing)tshuab txais yuav Siemens PLC tswj system thiab paub zoo txog hluav taws xob tswj Cheebtsam, nrog kev ua haujlwm ruaj khov., kev nyab xeeb thiab kev ntseeg siab.

2. Lub tshuab socketing uas ua haujlwm tag nrho siv ob txoj kev pneumatic lossis hydraulic. Thaum lub pwm socket raug rho tawm tom qab socketing, cov kav dej socket yuav raug xa mus rau hauv lub stacker los ntawm lub tshuab socketing.

3. Lub tshuab cua sov ntawm lub tshuab socketing tag nrho siv txoj kev cua sov rotary kom ntseeg tau tias cov yeeb nkab tau cua sov sib npaug thaum lub sijhawm cua sov. Lub kaw lus txias tuaj yeem zam kev hloov pauv ntawm cov yeeb nkab tom qab cua sov thiab xyuas kom meej qhov zoo ntawm cov yeeb nkab.

Daim ntawv teev qauv

| PVC Twin-yeeb nkab ntau lawm kab | |||||

| Qauv Kab | Txoj kab uas hla (hli) | Qauv Extruder | Qhov Tso Tawm Siab Tshaj Plaws (kg / h) | Ntev ntawm Kab (m) | Tag Nrho Lub Hwj Chim Teeb Tsa (kw) |

| BLS-63 PVC | 16-63 | BLE65/132 | 280 | 26 | 125 |

| BLS-63 PVC | 16-63 | BLE65/132G | 450 | 26 | 115 |

| BLS-110 PVC | 50-110 | BLE80/156 | 450 | 28 | 200 |

| BLS-160 PVC | 63-160 | BLE92/188 | 850 | 40 | 320 |

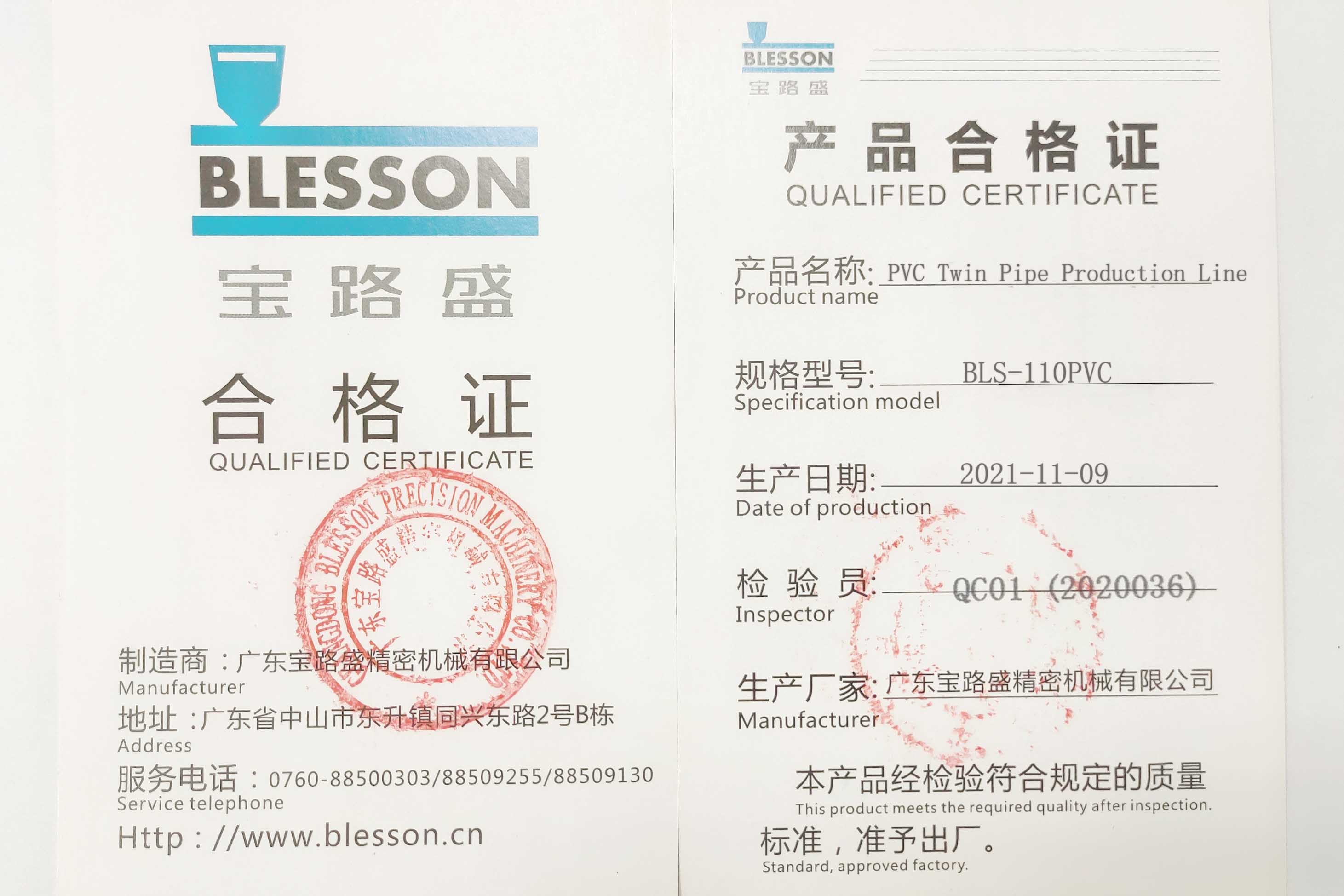

Kev Pov Thawj, Daim Ntawv Pov Thawj Ua Raws Cai

Guangdong Blesson Precision Machinery Co., Ltd. muab kev pabcuam lav ib xyoos. Thaum lub sijhawm siv cov khoom, yog tias koj muaj lus nug txog cov khoom, koj tuaj yeem tiv tauj peb ncaj qha rau kev pabcuam tom qab muag.

Guangdong Blesson Precision Machinery Co., Ltd. muab daim ntawv pov thawj tsim nyog rau txhua yam khoom muag, kom ntseeg tau tias txhua yam khoom tau raug tshuaj xyuas los ntawm cov kws tshaj lij thiab cov neeg kho qhov yuam kev.

Cov Ntaub Ntawv Txog Lub Tuam Txhab